Selecting the ideal wheel material is critical for ensuring efficiency and durability in any equipment or machinery. Different materials offer distinct advantages, from resistance to wear and tear to smooth operation across various surfaces. Understanding the specific demands of your environment—whether it involves heavy loads, frequent movement, or exposure to harsh conditions—can help determine which material will deliver optimal performance and reduce long-term maintenance costs. Making an informed choice improves functionality and enhances safety and reliability over time.

For industrial applications, investing in heavy duty caster wheels can significantly boost operational efficiency. These wheels are designed to handle substantial weight while maintaining smooth mobility, making them ideal for factory floors, warehouses, or any setting that demands strength and durability. Choosing the right material for these casters ensures they withstand rigorous daily use, resist damage, and provide a long service life, ultimately maximizing both performance and longevity of the equipment.

Performance Factors to Consider

The selection of the best wheel material depends on various factors such as load capacity, floor type, frequency of use, and environmental conditions. Heavy loads require more robust materials like steel or polyurethane, while light-duty applications may benefit from softer options like rubber. Noise levels and environmental conditions can also affect wheel longevity. Harder wheels are better for delicate flooring, while robust materials with high wear resistance provide longer lifespans and safer operation.

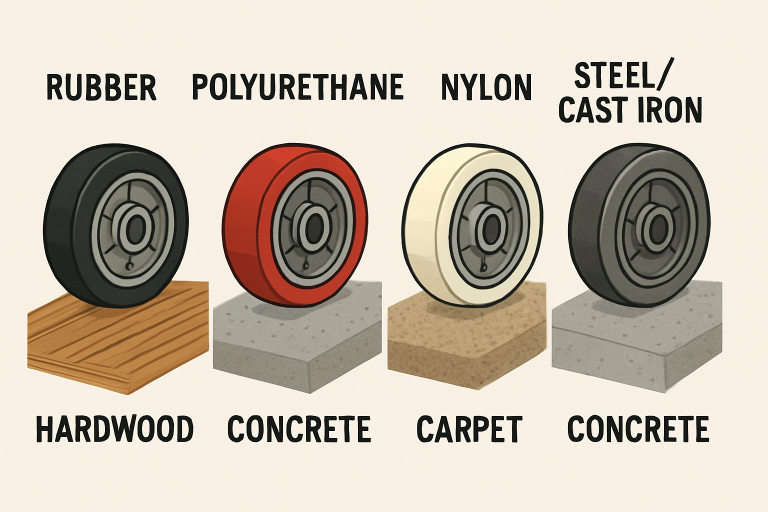

Common Wheel Materials and Their Benefits

- Rubber: Excellent shock absorption and grip make rubber wheels a top choice for quiet environments and delicate surfaces. However, they may show accelerated wear under continuous, heavy loads.

- Polyurethane: Valued for their resilience and chemical resistance, polyurethane wheels excel in mixed indoor/outdoor scenarios and withstand oil, grease, and other contaminants.

- Nylon: Lightweight and impervious to various chemicals, nylon wheels work best for medium-duty tasks but might be noisier and less gentle on flooring.

- Steel/Cast Iron: Designed for the heaviest loads and the harshest environments, these materials boast exceptional longevity but can compromise delicate floor finishes.

Each material serves a purpose, so selecting based on your predominant operational needs ensures durability and safety.

Application Scenarios for Different Wheel Types

Wheel application scenarios vary between settings. Office furniture uses rubber or soft polyurethane wheels for quiet transport and minimizing flooring risk. For durability, warehouses, factories, and construction zones require robust wheel types like steel or nylon. Hospital beds use thermoplastic rubber or polyurethane wheels for cleanliness and smooth operation, while airport luggage carts and industrial racks use cast iron or reinforced polyurethane for stability and performance.

Environmental Impact of Wheel Choices

Environmental responsibility is driving a shift towards sustainable wheel production and end-of-life management. Rubber wheels now contain recycled content, while metals like steel and cast iron are easily recyclable. Corporate responsibility organizations choose materials based on recyclability and toxicity profiles. Consistent maintenance supports green business initiatives.

Conclusion

Choosing the right wheel material is essential for ensuring efficiency, durability, and safety across various environments. By evaluating factors such as load, floor type, frequency of use, and environmental conditions, you can select wheels that provide optimal performance while reducing maintenance needs. Considering material benefits and application scenarios helps protect equipment, flooring, and operators. Thoughtful wheel selection enhances functionality and longevity and supports sustainable practices, making it a smart investment for productivity and environmental responsibility.

Leave a Reply